Bringing A High-Tech Range of Screw Conveyor System, Air Lock Valve, Bin Vibrating Aerator, Industrial Screw Conveyor, Etc., At Cost-Saving Prices!.

About Us

Jain MEP Engineering & Projects LLP was founded in October 2015 in New Delhi, India, with a clear vision: to serve custom machines, precision Spare-parts and consumable items for the bulk solids handling industry. Our Main Products are bulk material loading bellows (telescopic chute / Loading spout), Rotary airlocks, Screw conveyors, sleeve couplings, Fluidizing Pads, Non-return Valves for pneumatic lines (NRVs), Silo aerators etc.

We manufacture mainly loading bellows & in-house. And other products we buy directly from our associated manufacturers. We bargain hard to get the best price; our quality engineers and team inspect at all critical stages and then pass the savings on to you. We keep our costs low because every penny we save is yours.

With each successful project, our reputation grew and gradually expanded our customer base worldwide. Today, JMEP machines and parts can be found across India. We have also started serving the globe, working for some of the world's leading companies.

We are famous for our quick response, and we offer the best value for our products. We stay open for our customers throughout the day. With such a diverse team from many different places, we bring a unique perspective to everything we do.

Make your

enquiry now !

Talk to us! we will be glad to assist

you.

Product Gallery

-

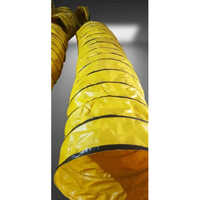

Telescopic Chute -

Unloading Chute -

Outer Bellows -

open truck Loading Spouts -

High Temperature Outer Bellow for Telescopic Chutes -

Outer cloth of loading spouts -

Loading Spout Outer Bellow -

Outer Bellow Of Loading Spout -

Integral Dust Collector -

Dust Collection Filter Bag -

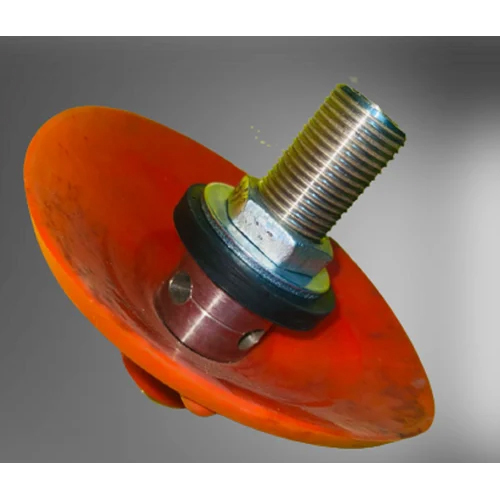

Rotary Vane Feeder -

Rotary Air Lock Valve -

Air Slide Fabric -

Diaphragm Type Non-Return Valve -

Fluidising Pads -

Bin Aerator -

Silo Aerators -

Silo Bin Aerator -

Vibrating Aerator -

Filter Bag Cage -

Bulker telescopic chute -

MS Fluidizing Pads -

Pneumatic Poppet Valve

Our Objectives

- Quality: To keep improving our offered quality with time by adopting higher standards and improving our testing & inspection facilities.

- Safety: To enhance safety in the workplace by making it more prolific and resourceful for employees.

- Efficiency and Costs: To continuously make our products more efficient and cost-friendly for the customers.

Infrastructural Facilities

At our ultra-advanced manufacturing premises located in Delhi (India), we have installed world-class machinery, devices and tools that are useful for producing bulk quantities of Vibrating Aerators, Fluidizing Pads, Screw Conveyors, Rotary airlocks, Air Slide Fabric, etc., regularly without affecting the quality of any single product. Besides this, our infrastructural facilities also help us in:

R&D And Design Capabilities

We have facilitated our R&D experts with the latest software like AutoCAD, operated by professionals with years of experience in the field. Also, they make 3D modelling on Autodesk Inventor. With these, we are consistently improving our design capabilities and optimizing the quality of our products.

Land & Storage Capacity

For the storage of quality-assured and finalized products, we have 2 distinct areas, which include 1250 Sq. Yards in Rai Industrial Area (Haryana, India) and 250 Sq. Yards in Rithala Industrial Area (New Delhi, India).

Lifting Capacity

For material handling, we have the latest technology of equipment that enables us to lift around 10 tons in-house.

Download Brochure

|

JAIN MEP ENGINEERING & PROJECTS LLP

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |